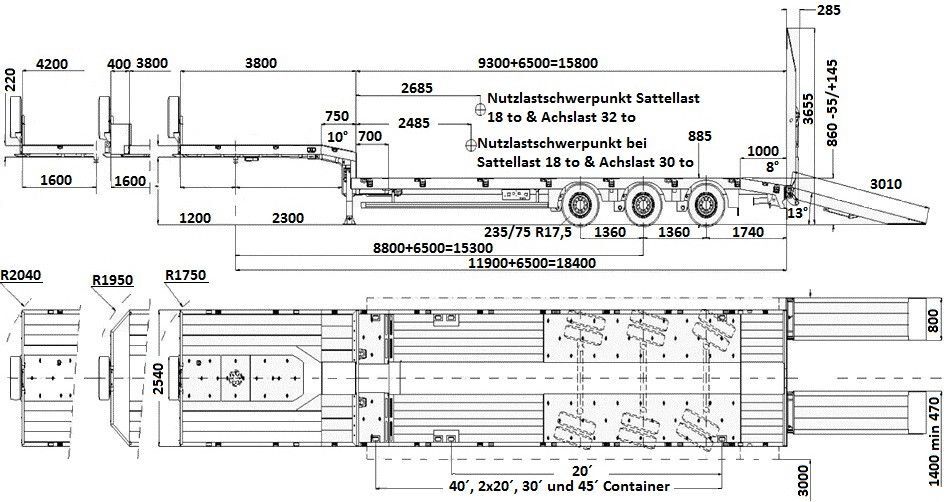

Semirremolque góndola rebajadas nuevo Faymonville MAX Trailer 3-Achs-Tele-Semi-zwangsgelenkt

Publicado: 6mes(es) 25d.

Publicado: 6mes(es) 25d.

¿Necesitas envío?

Inspección previa a la compra

Inspección previa a la compraGooseneck:

• Gooseneck with rear chamfer approx. 750 mm x 10°.

• 3 pairs of lashing rings (LC 5.000 daN).

• Hardwood floor 30 mm thick.

Loading floor in telescopic design:

• Loading floor in telescopic design with rear chamfer of approx. 1.000 mm x 8°.

• 5 pairs of lashing rings, foldable outwards (LC 5.000 daN).

• 3 pairs of lashing rings, foldable outwards (LC 10.000 daN).

• 1 pair of lashing rings, lying at the front of the loading floor (LC 10.000 daN).

• Cut-outs in the outer frame of the loading area for hanging straps (LC 2.000daN)

• Hardwood floor approx. 48 mm thick, over the axles checker plate.

Two-part steel ramps:

• 1 pair of two-part steel ramps (galvanized) approx. 2.750 + 1.400 x 800 mm with hardwood floor approx. 48 mm

thick.

• Ramps with hydraulically foldable parts, hydraulic lifting and lowering and hydraulically movable.

• Maximum load per pair: 40.000 kg

Landing legs:

• JOST landing legs (mechanical) with 2-gears for 24t lifting capacity (50t test load).

Axles and tyres:

• BPW-axles and suspension, all axles with hydro-mechanical forced steering.

• Technical axle load: 12.000 kg.

• Air suspension with lifting and lowering valve.

• Axle tools.

• Tyres 235/75 R 17,5.

Braking system:

• Braking system according to EU regulations with EBS-E (2S2M).

Steel construction:

• Steel construction made of high-strength fine-grained steels.

• Steel quality:

S355J2+N/S355MC (yield strength 355MPa)

S690QL/S700MC (yield strength 690MPa)

Painting:

• First-class and long-lasting corrosion protection of the standard shot-peened welding frame guaranteed by a

2-component (2K) zinc dust primer. A high-quality 2-component (2K) single-colour top coat.

• Trailer: MB 7350 nova grey.

• Rear section metallized and painted in RAL 9010 (pure white).

Electrical system:

• Electrical system according to EU regulations, lighting LED 24 volt ASPÖCK-NORDIK (ASS3)

• ASPÖCK-UNIBOX on the connection strip at the front with 24N, 24S, & 15-pin sockets

• Connection according to ISO

• 24N ISO-1185

• 24S ISO-3731

• 15-pin ISO-12098

Additional equipment:

• 2" king pin.

• A galvanized steel end wall approx. 400 mm high.

• Yellow-red air couplings on the front of the galvanized connection strip.

• 4 wheel chocks with holders on the bulkhead.

• A spare wheel with holder in front of the bulkhead.

• Electro-hydraulic unit.

• Follow-up steering can be operated from the front and rear using a cable remote control with pushbuttons,

with axle tracking control.

• Mount in the rear area of the gooseneck for ALU docking ramps.

• European reflector signs (red-yellow) on the rear of the trailer.

• Red reflective tape on the side, on the pull-out and on the back in accordance with EU regulations.

• On the gooseneck and on the ramps on the left and right, a holder for the warning signs including a socket.

• A bracket for a warning light at the rear of the trailer.

• Galvanized folding supports under the slope of the loading area.

• Control valves for the ramps mounted on the right side of the trailer.

• A mud flap at the rear of the trailer.

• Cover plates to bridge the space between the ramps and the loading area

• Manual and description on USB stick

• ALU side walls and rear wall can be plugged onto the gooseneck, approx. 2.440 x 400 mm (L x H).

• The rear galvanized stanchions are removable. (Length of the body approx. 2.560 mm).

• 4 pairs of WADER container bags in the loading area for a 20ft, 2x 20ft, 40ft or a 45ft container.

• 7 pairs of stanchion pockets 100 x 50 mm in the outer frame of the loading area.

• Galvanized extensions, extendable by approx. 230 mm on each side.

• A tool box INOX 1.500 x 390 x 810 under the loading area on the right in the direction of travel.

• Square climbing strips 20 x 20 mm every 200 mm on the outer frame of the sloping loading area.

• Lifting axle on the front axle controlled by TEBS E depending on the current axle load and the current loading

status.

• BEKAMAX (Pico) central lubrication system with normal grease NLGI-2 and with removable protection around

the pump.

• 4 warning signs approx. 423 x 423 mm, extendable by approx. 400 mm, with an LED position light.

• On the warning signs a bracket for a warning light.

• Radio remote control for tracking in addition to the cable remote control, with LED indicator lights on the

receiver as lane control.

• A coated layer of sand on the checker plates, over the king pin and the loading area to prevent slipping.

• Speed sticker 80 km/h on the rear and on both sides.

• Load manometer to determine the axle loads including load diagram.

• HRM metallization (High Resistance Metallization) of the outer frame.

• Complete steel construction shot-blasted, then the defined visible surfaces metallized with ZINACOR 850 (zinc

85% - aluminum 15%), hot-coated.

¿Necesitas envío?

Obtenga una cotización de envío

¿Necesitas envío?

Obtenga una cotización de envío